Edited by Lingo Shih, Engineer at Product R&D Division, CoreTech System (Moldex3D)

- Customer: PEGATRON Corporation

- Region: Taiwan

- Industry: Electronics

- Solution: Moldex3D Advanced Package; Flow, Pack, Cool, Warp, Fiber, Warp, FEA Interface

PEGATRON Corporation was founded in 2008. With abundant product development experience and vertically integrated manufacturing, they are committed to providing clients with innovative design, systematic production, and manufacturing service. PEGATRON has combined EMS and ODM industries to become an emerging Design and Manufacturing Service (DMS) company. (Source: https://www.PEGATRONcorp.com)

Summary

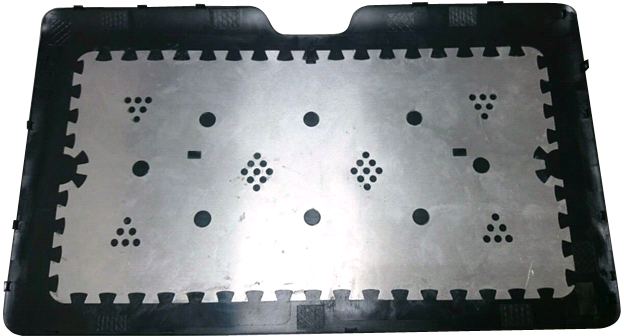

In order to create lighter, slimmer parts, PEGATRON engineers were tasked to reduce the thickness of a tablet bottom base case cover from 1.5mm to 1mm and add a metal insert part, 0.5mm thickness, to the original design (Fig. 1). Thin-wall molding can be challenging and create many problems such as filling imbalances and structural integrity. PEGATRON engineers used Moldex3D simulation software to optimize mold designs, reduce shrinkage and validate the strength of the part through integration with FEA analysis.

Fig. 1 This part with a metal insert and thin wall

Challenges

- Short shots

- Air traps

- Shrinkage caused by different wall thickness

Solutions

With Moldex3D, engineers at PEGATRON were able to analyze the causes of warpage, successfully reducing the Z-displacement by 92%, and assure that the part strength requirements were met with the integration with ANSYS structural analysis.

Benefits

- Met target part thickness of 1mm, reducing thickness by 23%

- Significantly reduced warpage by 92%

- Reduced pressure loss by 8.3%

- Reduced scrap by 13%

- Saved more than 6% of manufacturing costs with insert molding

Case Study

In the molding process of electric parts, cooling is a key factor of final product performance. It is common to use fans for heat dissipation, but in some fanless cases, we can only use a thermal pad made from aluminum or copper as a part insert. The thicker and wider the metal plate is, the better the cooling efficiency will be. The Z-height of the product, in this case, is fixed because of its specification. Therefore, if the thickness of the metal plate increased, the part thickness must be decreased. Also, the structure has to be strong enough to meet the product specification.

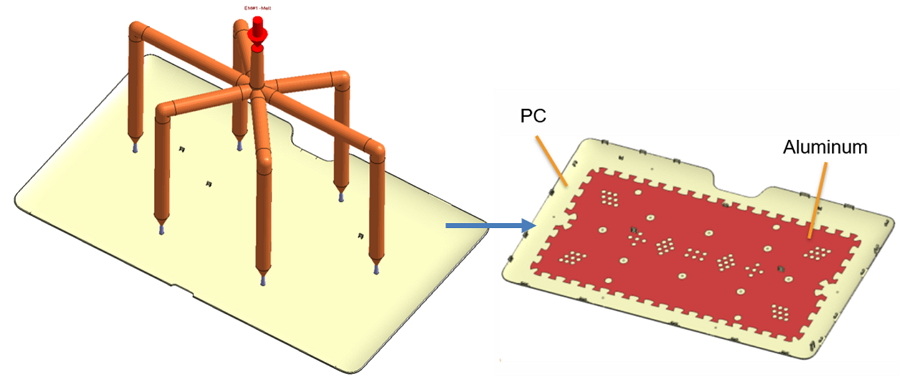

PEGATRON preformed thermal tests through their existing mold with a metal insert and found better dissipation results. Therefore, they decided to modify the original mold and part design (Fig. 2). After that, they tried to improve the production process, product quality, and structure strength through 3 stages.

Fig. 2 The original (left) and modified (right) part designs

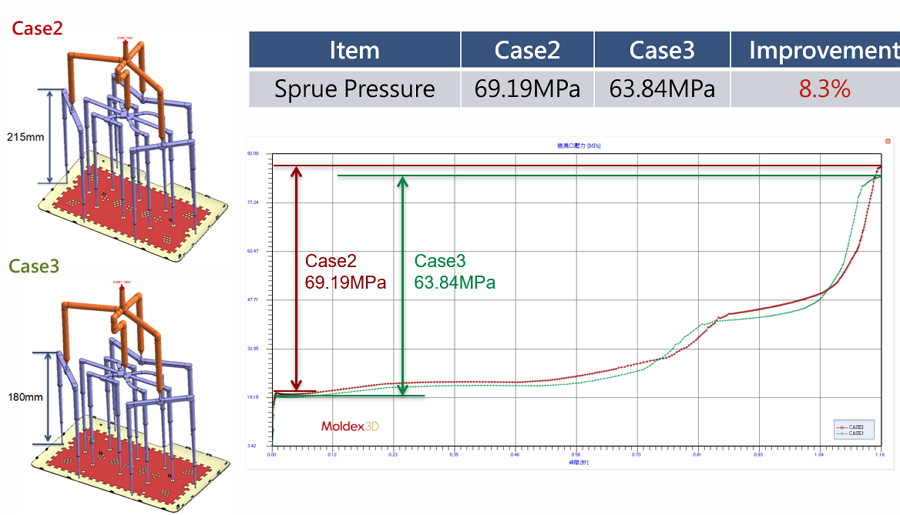

Through the Moldex3D Injection Module, PEGATRON found that the sprue pressure would get up to 135 Mpa due to the thin part. Thus, they considered to decrease the length of the runner and used Moldex3D to validate the original and revised designs (Fig. 3). As a result, they found the pressure loss had been reduced by 8.3% and the scrap had been reduced by 13% in Case 3. Therefore, they decided Case 3 as the optimized design.

Fig. 3 The sprue pressure comparison of different runner length designs

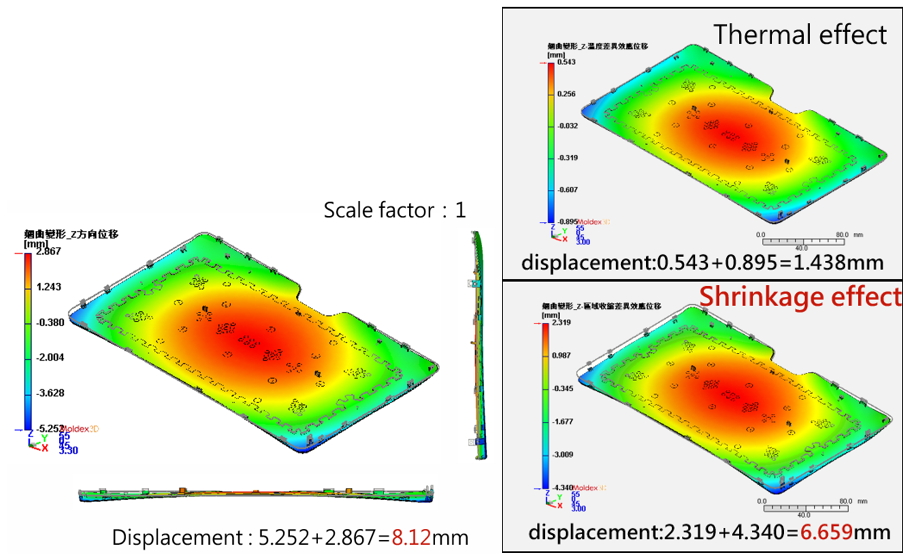

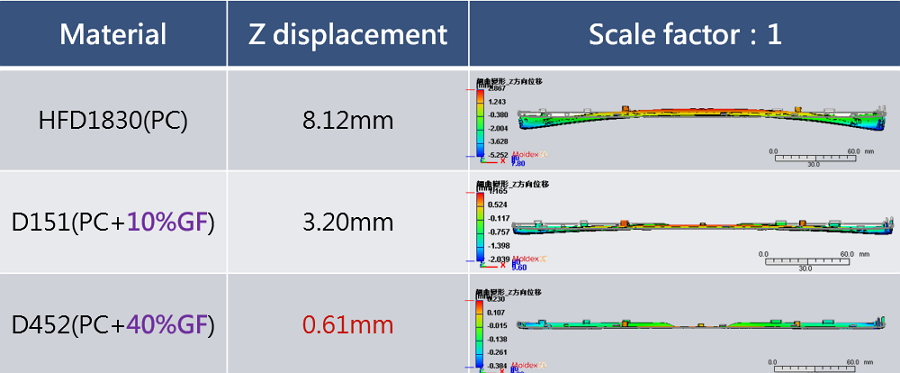

Next, they tried to improve the warpage. Moldex3D showed the largest warpage of Z-direction was 8.12mm, which was beyond the specification 1.0mm. Furthermore, the warpage simulation result indicated the shrinkage effect impact was greater than the thermal effect (Fig. 4). To fix this problem, PEGATRON tried to add different percentages of glass fiber content materials into the product and use Moldex3D to validate the warpage results. They found the filler could effectively reduce the warpage to meet the specification (Fig. 5). The reason was that fiber would orientate along the filling direction (X-axis) to resist the shrinkage.

Fig. 4 The warpage results of the original material

Fig. 5 The displacement comparison between the materials with different fiber filler percentages

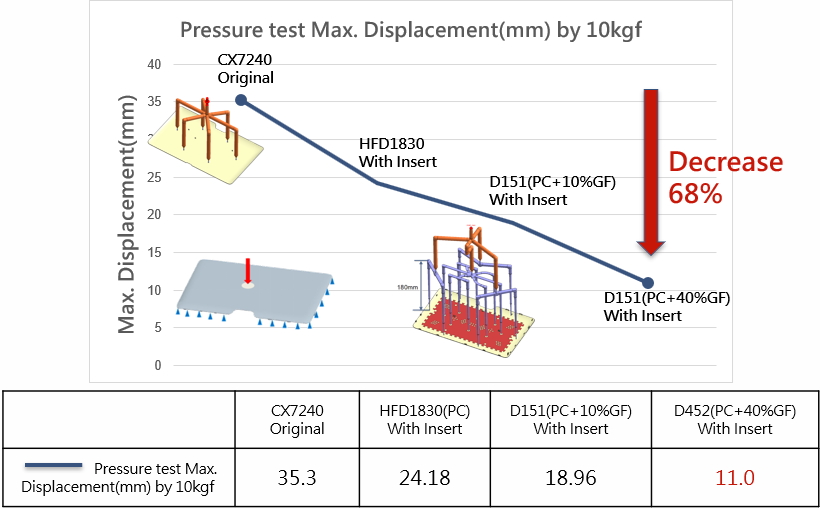

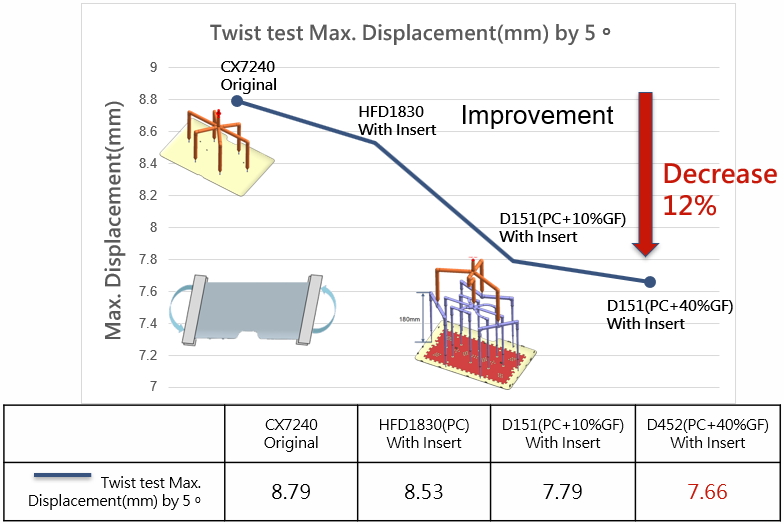

At the last stage, PEGATRON checked if the product structure was strong enough or not. They utilized Moldex3D FEA interface for further stress analysis considering the molding induced factors. After running the pressure and twist analysis, they found the part insert and materials with fillers could effectively help reduce the displacement in both tests (Fig. 6).

Fig. 6 The pressure test and twist test results of different materials and part designs

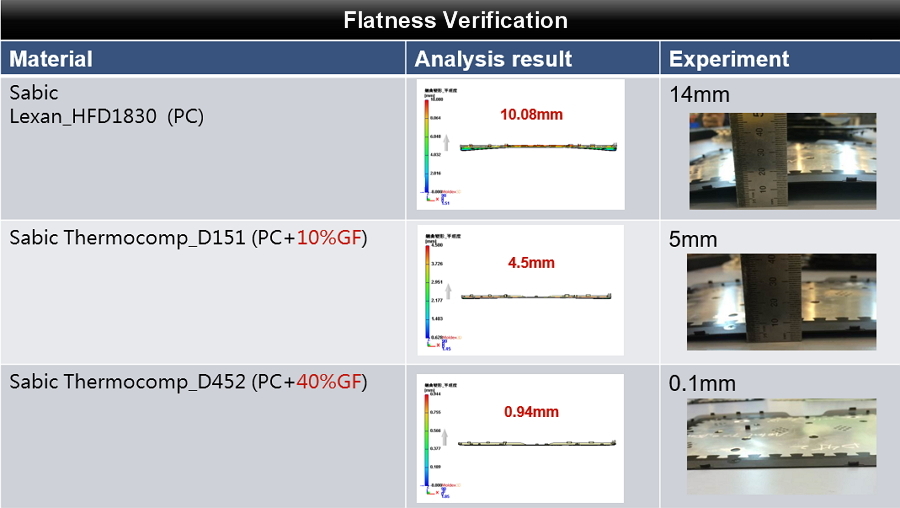

Lastly, PEGATRON verified the analysis result with the experiment and found the flow patterns of simulation and experiment have the same trends. As for the flatness verification, the experiment results with different materials were all consistent with the simulation results (Fig. 7).

Fig. 7 The flatness verification with the experiment results

Results

PEGATRON utilized the Moldex3D Advanced package to improve the product and mold designs. Through Moldex3D’s analysis, they also found the main factors of warpage and solved this issue by replacing the materials. As a result, the real molded product successfully met the specification for structural strength and deformation.

I. Strong R & D strength:

II. Excellent product performance:

III. Wide adaptability:

IV. Reliable quality:

V. Production process:

Our products

Swing Motor Excavator,Excavator Swing Motor Assy,Excavators Swing Motor

XINGTAI ZHONGWEI ZHUOTE HYDRAULIC TECHNOLOGY CO.,LTD , https://www.zwzhtehydraulic.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)